Product Description

In the world of material processing, efficiency and precision are paramount. Planetary mills are renowned for their ability to achieve ultra-fine grinding, making them essential tools in various industries. Central to their effectiveness are the grinding media used, with nano-polished zirconia grinding spheres standing out for their exceptional properties. These spheres offer low friction and high efficiency, ensuring optimal performance in planetary mills.

Zirconia grinding spheres are crafted from zirconium oxide (ZrO2), a material known for its remarkable wear resistance, high strength, and chemical inertness. These properties make zirconia spheres ideal for grinding processes that require minimal contamination and high precision. The nano-polished finish further enhances their performance by reducing friction, which in turn increases grinding efficiency.

- Low Friction: The nano-polished surface minimizes friction, reducing energy consumption and wear on the planetary mill.

- High Efficiency: Enhanced grinding efficiency leads to faster processing times and finer particle sizes.

- Wear Resistance: Zirconia's durability ensures a longer lifespan for the grinding media, reducing replacement costs.

- Chemical Inertness: Prevents contamination of the sample, maintaining the purity of the ground material.

Planetary mills utilize grinding spheres to achieve ultra-fine grinding of various materials. Zirconia spheres are particularly suited for applications involving fibrous, abrasive, and hard samples. Their ability to maintain structural integrity under high stress makes them ideal for demanding processes in industries such as ceramics, electronics, and pharmaceuticals.

- Ceramics: Used in the production of ceramic powders and glazes, zirconia spheres ensure consistency and purity.

- Electronics: Essential for grinding electronic ceramic powders, contributing to the development of advanced electronic components.

- Pharmaceuticals: Ensures the purity and consistency of active pharmaceutical ingredients through contamination-free grinding.

When selecting grinding media for planetary mills, it's crucial to consider the material's properties and the specific requirements of the application. Zirconia grinding spheres are often compared to other materials like hardened stainless steel, sintered corundum, and hardmetal tungsten carbide.

- Density: With a density of 5.7 g/cm³, zirconia spheres offer optimal grinding efficiency compared to lighter materials like agate (2.65 g/cm³).

- Hardness: Zirconia's superior hardness ensures effective grinding of hard and abrasive materials, outperforming softer options like sintered corundum.

- Contamination-Free: Unlike steel or tungsten carbide, zirconia's chemical inertness prevents unwanted reactions with the sample.

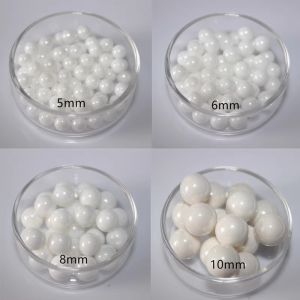

| Diameter(mm) | Each ball weight(g) | 100g balls qty(pcs) |

| 1 | 0.00314 | 31847 |

| 2 | 0.02512 | 3981 |

| 3 | 0.08478 | 1180 |

| 4 | 0.20096 | 498 |

| 5 | 0.3925 | 255 |

| 6 | 0.67824 | 147 |

| 7 | 1.07702 | 93 |

| 8 | 1.60768 | 62 |

| 10 | 3.14 | 32 |

| 12 | 5.42592 | 18 |

| 15 | 10.5975 | 9 |

| 20 | 25.12 | 4 |

●Chemical Composition:

| Composition | ZrO2 | Y2O3 + Others |

| Content % | 94.6 | 5.4 |

●Physical Properties:

| Specific Gravity g/cm3 | Bulk Density kg/L | Hardness Mohs | Hardness Hv | Fracture Toughness MPam1-2 | Crushing Load Kg.f (Φ0.3mm) | Grain size um | Sphericity (%) |

| ≥6.03 | ≥ 3.76 | 9 | ≥1210 | 9 |

8.2

| ≤0.3 | ≥98 |

40times under microscope for 0.3mm YSZ ball

● Inner structure:

● Size distribution:

| product name: | Yttria stabilized zirconia bead | size: | Φ0.3mm |

| 100pcs test result by selected random(unit: mm) |

| 0.28 | 0.29 | 0.3 | 0.31 | 0.32 |

| 0.28 | 0.29 | 0.3 | 0.31 | 0.32 |

| 0.28 | 0.29 | 0.3 | 0.31 | 0.32 |

| 0.28 | 0.29 | 0.3 | 0.31 | 0.32 |

| 0.29 | 0.29 | 0.31 | 0.31 | 0.32 |

| 0.29 | 0.3 | 0.31 | 0.31 | 0.32 |

| 0.29 | 0.3 | 0.31 | 0.31 | 0.32 |

| 0.29 | 0.3 | 0.31 | 0.31 | 0.33 |

| 0.29 | 0.3 | 0.31 | 0.31 | 0.33 |

| 0.29 | 0.3 | 0.31 | 0.31 | 0.33 |

| 0.29 | 0.3 | 0.31 | 0.32 | 0.33 |

| 0.29 | 0.3 | 0.31 | 0.32 | 0.33 |

| 0.29 | 0.3 | 0.31 | 0.32 | 0.33 |

| 0.29 | 0.3 | 0.31 | 0.32 | 0.33 |

| 0.29 | 0.3 | 0.31 | 0.32 | 0.33 |

| 0.29 | 0.3 | 0.31 | 0.32 | 0.33 |

| 0.29 | 0.3 | 0.31 | 0.32 | 0.34 |

| 0.29 | 0.3 | 0.31 | 0.32 | 0.34 |

| 0.29 | 0.3 | 0.3 | 0.3 | 0.36 |

| 0.29 | 0.3 | 0.3 | 0.3 | 0.3 |

|

| | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

●Features:

It has high density and hardness, making it suitable for high-quality products, such as ceramic inking, automobile, paints and coating.

It is suitable for high-efficiency horizontal mills and basket mills.

Low contamination of the milling product.

It is suitable for industries requiring nano-sized particles.

●Pakage:

25KG/Plastic Drum, 800-1000KG/Pallet with shrink wrapped

●Storage:

The grinding media should be stored in a dry and clean place.

Factory equipment

Exhibition & Partner

Case

Ship to philipine

Ship to Germany

FAQ

-

Are zirconia beads suitable for wet and dry grinding?

-

How do I choose the right size of zirconia beads?

-

What is the density of zirconia grinding beads?

-

Are zirconia beads chemically inert?

-

Yes, they are chemically inert and resistant to most acids, alkalis, and solvents, making them suitable for a wide range of materials.